The use of and demand for electronics has grown to unprecedented levels, fueled by new technologies and our reliance on connectivity in our personal and professional lives. And this has rapidly evolved to meet our demands during the pandemic. With our reliance on all things electronic comes a hefty impact of electronic waste (“e-waste”). Let’s examine the challenge, associated risks, and what companies can do to incorporate e-waste into the long-term sustainability strategy.

What is e-waste?

E-waste has traditionally been classified as computers, servers, monitors, tablets, printers, and cell phones. In today’s tech-enabled world, this term includes many more products used in households and businesses—household appliances and devices, toys, tools, music, cars, and wearables. When these goods reach the end of their useful life, they become e-waste.

According to the 2020 UN Global E-waste Monitor, e-waste is the world’s largest waste stream globally, often contains materials that are conflict-ridden and toxic to human health and the environment, and very little is recycled. E-waste also contains valuable materials, such as cobalt, lithium, palladium, copper, and gold, whose value is lost when not recovered through recycling channels.

| The world generated 53.6 million metric tons of e-waste in 2019. Only 17.4% of that was recycled. The fraction not recycled (82.6%) represents $47 billion in lost value from materials that could have been recovered, including cobalt, palladium, copper, and other conflict minerals. Sources: 2020 UN Global E-waste Monitor, GESP 2020 How E-waste Management Market Became a Highly Profitable Industry 2020: Revenue Analysis and Growth Opportunity, AP Newswire 2020 |

The hidden risks of e-waste

Environmental impacts: E-waste contains many materials, such as lead, mercury, per- and polyfluoroalkyl substances (PFAS), brominated flame retardants (BFR), chlorofluorocarbons (CFC), hydrochlorofluorocarbons (HCFC), and persistent organic pollutants (Borthakur 2016; Seeberger et al. 2016). When e-waste is not recycled, these chemicals contaminate landfills, adversely impacting the water supply through leachate, and polluting the land. Communities located near landfills are particularly susceptible to chemical exposures resulting from improper e-waste disposal. Environmental contamination from recycling operations is common, impacting human health in neighboring communities (Avakian 2014).

Health & Safety impacts: The recycling process for e-waste requires manual disassembly of many electronics, exposing workers to repetitive stress and other physical injuries. The disassembly process also presents the potential for worker exposure to airborne contaminants such as lead, mercury, and combustible dust, which cause significant health impacts. Following disassembly, the treatment of e-waste for recovery of precious metals involves hazardous chemicals and high-risk processes, such as acid processing and smelting, creating high-hazard work environments. Most e-waste treatment occurs in developing countries, which often lack the regulatory controls, safety infrastructure, and culture to keep their workers safe. Research by the World Health Organization (Grant et al. 2013) identified associations between e-waste exposure and thyroid dysfunction, adverse birth outcomes, behavioral changes, decreased lung function, and adverse changes at the cellular level in children.

Companies well acquainted with e-waste risks use a combination of techniques to mitigate these issues, which may include downstream recycling vendor due diligence and verification, extended producer responsibility (EPR) programs, internal corporate standards, and contract terms. Companies that have identified e-waste risks for the first time face a new business risk. As more products become “smart” and connect to the internet, companies are now seeing electronics emerge as a material waste stream, making e-waste risks material to their business.

In addition, consumers and governments are putting on increased pressure for programs that allow for product takeback and resource recovery. Some regions are seeing regulatory action on e-waste, such as the European Union’s recast of the Waste from Electrical and Electronic Equipment (WEEE) Directive. Companies are committing to climate and zero-waste goals in response to shareholder and customer pressure, further elevating the corporate profile on achieving a sustainable business outcome (European Environment Agency 2012). Emerging regulations, market drivers, customer expectations, corporate carbon and net zero goals, and shareholder demands are all key risks to the broader e-waste challenge.

Approaches to the e-waste challenge

Companies are in various stages of their e-waste management journey—whether due to recent recognition of potential e-waste in new products or improving programs for existing products. Wherever a company sits in the electronics product lifecycle, the first steps are to identify material risks presented by e-waste, assess the actions already taken, and map out a strategy for moving forward.

At an early stage in its e-waste management journey, one market-leading wearables manufacturer recognized a potential e-waste risk in a new product and engaged ERM for strategic guidance to understand the critical elements of e-waste risk, such as downstream supply-chain risks and auditing of vendors. Due to the range of impacted business functions—which included supply chain, logistics, vendor management, procurement, legal, and product development staff—it was critical to understand internal priorities so that the standard and program would mitigate risks and holistically address the company’s needs. ERM facilitated these internal stakeholder workshops, which socialized the client’s newly formed position and facilitated the necessary buy-in. Following the workshops, ERM worked with the client to author a corporate e-waste management standard, and design and implement a vendor verification program for e-waste recyclers. The corporate leadership team recognized both the standard and the program as critical to helping the manufacturer achieve their zero-waste goals.

The approach looks different for a company further along on their e-waste management journey. A major global technology company—a decade into their program—was looking to improve oversight and track transparent management of e-waste through their third-party recycler network. The company is highly attuned to the brand and reputational risks that the downstream supply chain poses—labor, global exposure, worker safety, and environmental contamination issues. With this in mind, ERM implemented a global recycler verification program and local support to assist recyclers with addressing corrective actions. The clear result has been a stronger EHS performance. To date, ERM has audited more than 300 e-waste recyclers in 30+ countries as part of this program, and the company has more compliant and dependable recyclers to handle their recycling streams and in turn manage their supply-chain risks.

Thinking big picture, long-term

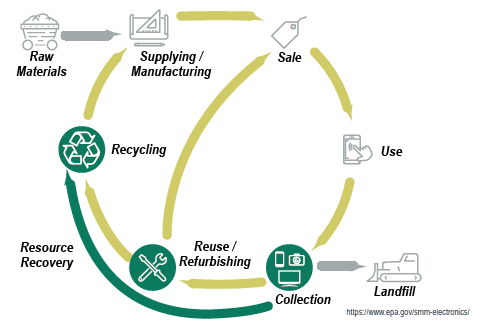

While companies are addressing the brand and reputational risks that e-waste presents, the conversation around e-waste continues to evolve. As the world transitions from a linear economy to a circular one, mining of prime materials needed for electronics is not sustainable for business in the long term. While the technology for efficiently recovering and recycling key components is still developing, more companies are investing in recovery and recycling technologies, as it contributes to the future bottom line. Harnessing the value from existing e-waste will save billions in material costs, and significantly reduce the carbon footprint of a product. Companies need to discuss how to harness resource recovery from e-waste as a strategic business advantage in the transition to a circular economy.

Companies ambitious enough to close the loop for their products will not only be market leaders in sustainability, but will also have the potential to recognize cost savings by tapping into the growing e-waste management market, expected to reach $102.62 billion by 2027 (AP Newswire 2020). The approach must be two-pronged: understand and mitigate the risks associated with e-waste now, and harness the value of the circular economy transition through product redesign and reuse of valuable materials.

Looking forward

Every company has different needs. You must customize solutions to fit your culture, market needs, and risk profile. Here are some ideas to get started:

- Quantify the e-waste stream and its associated costs. To fully understand the impact of e-waste on your company, identify what you are generating and in what quantities, and the costs associated with managing these waste streams.

- Understand how e-waste is handled and processed to end-of-life. The intrinsic value of electronics means that secondary markets are key to extracting components for reuse and recycling. Seek full transparency for electronics end-of-life to verify you are managing and recycling e-waste properly without creating additional risks and exposures to workers or the environment.

- Assess options for circularity. As the world transitions from a linear to a circular economy, technology companies are on a journey to redesign products to make it easier to recover the valuable components that can be reused for future products. Conduct lifecycle assessments for products, quantify Scope 3 emissions associated with e-waste recycling practices, and explore how changes in vendors or business practices can reduce overall environmental impact.

- Explore how changes in e-waste management contribute to your company’s sustainability goals. Assess whether e-waste is a material issue for your organization. Fully understand the challenges and opportunities that can have a material impact on achieving corporate zero-waste, carbon neutral, and climate change goals.

E-waste presents unique challenges and risks to companies in our tech-enabled world, and ERM is partnering with many companies to change the narrative on e-waste. From internal changes in corporate policy, to vendor management and product redesign, the potential solutions to combat the e-waste problem present significant opportunities for companies to differentiate themselves in an increasingly competitive landscape. As your company considers new products to take to market, consider the e-waste implications and start a broader conversation. Whether you are in the early stages in your understanding of this issue, or seeking specific improvements to a mature program, ERM is excited to be part of the broader discussion on how companies navigate their e-waste management journey.

References:

AP Newswire. 2020. How E-waste Management Market Became a Highly Profitable Industry 2020: Revenue Analysis and Growth Opportunity. 25 August. https://apnews.com/press-release/wired-release/38fc8cb6941ded5e075c2e9913f9e5dd.

Avakian, M. 2014. “E-waste: An Emerging Health Risk.” Global Environmental Health Newsletter, National Institute of Environmental Health Services. February. https://www.niehs.nih.gov/research/programs/geh/geh_newsletter/2014/2/spotlight/ewaste_an_emerging_health_risk_.cfm

Borthakur, A. 2016. “Health and Environmental Hazards of Electronic Waste in India,” Journal of Environmental Health 78, no. 8: 18–23. April.

ERM. 2020. “Circular Economy.” From the What to the How, Sustainability report 2019. https://www.erm.com/sustainability-report-2019/impact-with-clients/circular-economy/.

European Environment Agency. 2012. “Waste electrical and electronic equipment (WEEE) Directive 2012/19/EU” Policy Document. https://www.eea.europa.eu/policy-documents/waste-electrical-and-electronic-equipment.

Global E-waste Statistics Partnership (GESP). 2020. UN Global E-waste Monitor 2020. Prepared by UN University (UNU), the International Telecommunication Union (ITU), and the International Solid Waste Association (ISWA), in collaboration with the UN Environment Programme (UNEP). http://ewastemonitor.info/

Grant, K., F. Goldizen, P. Sly, M. Brune, M. Neira, M. van den Berg, and R. Norman. 2013. “Health consequences of exposure to e-waste: a systematic review.” The Lancet, Global Health, vol. 1, no. 6, e350-e361, 1 December. https://www.thelancet.com/journals/langlo/article/PIIS2214-109X(13)70101-3/fulltext.

Seeberger, J., R. Grandhi, S. Kim, W. Mase, T. Reponen, S. Ho, and A. Chen. 2016. "SPECIAL REPORT: E-Waste Management in the United States and Public Health Implications." Journal of Environmental Health 79, no. 3: 8–17. October.