Water, Fuel, Electricity, Steam, and Energy costs are rising. Access is increasing in complexity, investment in energy infrastructure is declining, and regulations are intensifying. Never has there been a greater need to ensure your energy-intensive production facilities are operating as efficiently as possible.

But you have questions: what energy efficiency opportunities are available to you? Can you justify the investment required for an optimization initiative? Is there low-hanging fruit that could give you quick returns for minimum cost? Where do you start? Is there an opportunity to decrease emissions in the process?

Your Energy Lifecycle Optimization journey starts with an energy assessment technique and ends in operational changes that can have a material impact on your bottom line.

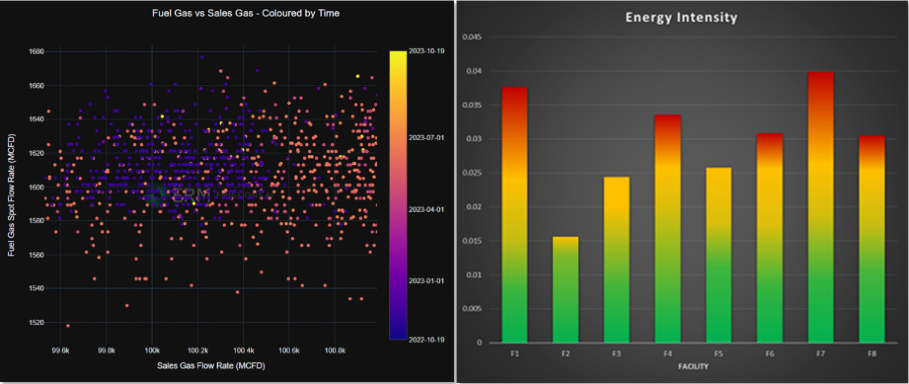

Combining the latest in data science and operational expertise, ERM have created the Energy Variability Assessment. With access to a sample of up to a year of historical data from as few as 5 or 6 data points, this assessment can quantify the opportunity within your facility. This can help build a business case and ensure the team is focusing on delivering the biggest impact. All in just 2 weeks

If you need help quantifying your energy efficiency opportunity, or you have a portfolio of facilities and you would like to know where to start, then join us to hear how companies like yours are using this technology to improve Energy Lifecycle Optimization.